Taniglass Co.,Ltd

SOLUTIONS – INNOVATION – EFFICIENCY

Taniglass ITP., JSC, formerly known as Taniglass Corporation, has been operating in the post-glass processing industry for nearly 20 years. Since its establishment, Taniglass has continuously grown to become a leading glass processor specializing in safety glass, soundproof and thermal insulation glass, fire-resistant glass, and various other types of high-performance glass products.

Products & Services

Currently, Taniglass operates two manufacturing facilities located in Tan Do Industrial Park, Duc Hoa Commune, Tay Ninh Province. These factories are equipped with advanced machinery, modern production lines, and are staffed by a team of highly skilled professionals. This enables us to produce a wide variety of high-quality glass products that meet the diverse needs of the market.

Address: Lot D3, Road No. 2, Tan Do Industrial Park, Duc Hoa Commune, Tay Ninh Province

About the factory Taniglass

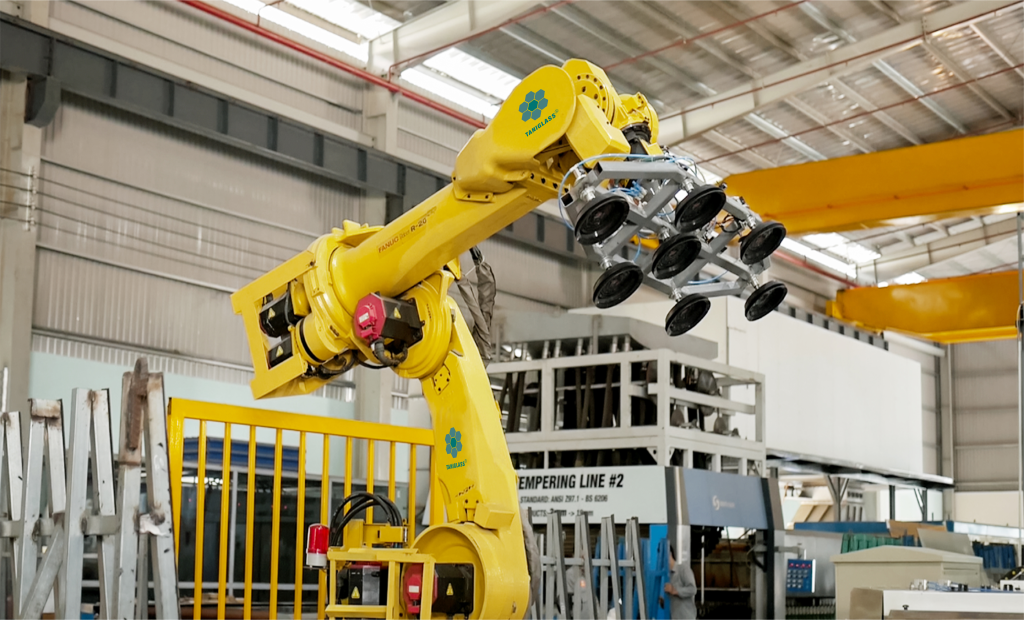

With the motto “Improving to be better every day”, Taniglass leverages a team of highly skilled professionals, state-of-the-art equipment, and a synchronized management system covering every stage—from production planning to quality control.

Currently, Taniglass operates two high-capacity factories located in Tan Do Industrial Park, Tay Ninh Province, with over 10,000 square meters, capable of supplying more than 1.000.000 m² of finished glass products annually. These include a wide range of high-performance glass types such as safety glass, soundproof and thermal insulation glass, fire-resistant glass, and decorative glass including: tempered glass, PVB laminated glass, printed glass, soft-coated low-E tempered insulated glass, EI fire-resistant glass, E fire-resistant glass, and more.

Taniglass is ready to deliver comprehensive glass solutions safety – energy efficiency – and aesthetics for private residences, office towers, hotels, resorts, and commercial centers—both domestically and internationally.

A Journey of Growth and Development

20 YEAR

Taniglass ITP., JSC, formerly known as Taniglass Corporation, has been operating in the glass processing industry for nearly 20 years. Since its establishment, Taniglass has continuously evolved to become a leading glass fabricator, specializing in the production of: tempered glass, heat-strengthened glass, laminated safety glass, energy-saving glass, soft-coated Low-E insulated tempered glass (IGU), EI fire-resistant glass, E fire-resistant glass, and more

Establish

Inauguration of the first tempered glass factory in Ho Chi Minh City

Develop

Converted to Taniglass Company Limited

Orientation

Expanding factory in Tan Do Industrial Park (Long An) with over 10,000 square meters and upgrading technology

Stretch Yourself

Achieved more than 900 projects, expanded exports; increased investment in modern equipment

Quality is the foundation – Technology is the leverage – People are the core value.

Project

900Supplying over 900 domestic and international projects with a diverse range of glass products: tempered glass, heat-strengthened glass, laminated safety glass, energy-saving glass, soft-coated Low-E tempered insulating glass (IG), EI fire-resistant glass, E fire-resistant glass, and more.

Service

34Supplying products across all 63 provinces and cities nationwide

Human

10010 engineers – 12 office staff – 78 machine operators and QC personnel.

Factory

02Lot D3-C4, Street No. 2, Tan Do Industrial Park, Duc Hoa Commune, Tay Ninh Province (formerly Long An Province).

Product

10More than 10 main product lines with over 100 different types of glass products, including: tempered glass, heat-strengthened glass, laminated safety glass, energy-efficient glass, soft-coated Low-E tempered insulated glass (IGU), EI fire-resistant glass, E fire-resistant glass, and more.

Become the leading construction glass brand in Vietnam and reach out to Southeast Asia, pioneering in safety – energy efficiency – and aesthetics glass solutions for all architectural works.

Creating safe, sustainable and classy living and working spaces through providing high quality glass products, professional services and advanced technology.

Quality as the foundation – Technology as the leverage – People as the core value.

We believe that each piece of glass is not just a material, but a complete solution for safety, aesthetics, saving energy and performance.

Dedication: Serving customers with sincerity and responsibility

Quality: Committed to the highest product standards

Innovation: Continuously improving technology and processes

Collaboration: Building lasting partnerships with customers and partners

Responsibility: Accountable to products, people, and the environment

Professional – Collaborative – Disciplined – Human-centered

Glass Manufacturing and Fabrication Processes

CNC Processing Line

Capable of cutting any shape from:

-

CAD files

-

Scanned templates

-

Custom design patterns

Applicable glass types:

-

Float glass

-

Mirror glass

-

Solar control glass

-

Soft-coated Low-E glass

-

Hard-coated Low-E glass

-

Patterned laminated glass

-

Other specialty architectural glass types

CNC Glass Edge Grinding

Edge profiles available:

-

Beveled edge

-

Duckbill edge (OG edge)

-

Pencil edge (round edge)

Supported shapes:

-

Rectangular

-

Parallelogram

-

Irregular/custom shapes

-

Soft-coated Low-E glass

-

Hard-coated Low-E glass

Waterjet Glass Cutting

-

Capable of drilling at any position on the glass panel

-

Requires strict compliance with specifications for hole position, diameter, and cutout size

-

Ensures structural integrity during the tempering process and prevents glass breakage

- Capable of processing soft-coated Low-E glass

Full Convection Tempering Furnace – Dual Heating Chambers

-

Glass thickness range: 2.8 mm to 19 mm

-

Maximum glass size: 3050x5100mm and 2650 × 6100 mm

-

Capable of tempering specialized glass types such as:

-

Soft-coated Low-E glass

-

Solar control glass

-

And other high-performance coated glass types

-

Laminated Safety Glass Production

-

Thickness range: 4.38 mm to 50 mm

-

Maximum size: 3000×7000 mm

Taniglass specializes in PVB-laminated tempered glass, achieved by integrating advanced tempering technology with PVB lamination techniques — making it one of the company’s key strengths in safety glass manufacturing.

Integrated IGU Production Line

-

Equipped with automatic sealing robot and online Argon gas filling system (gas is injected automatically during the glass pressing process)

- Capable of processing soft-coated Low-E glass

-

Maximum unit size: 3050x5100mm, 2650x6100mm

Fire-Resistant Glass Processing

-

Includes fire-resistant sealant application

-

Autoclave lamination for fire-rated glass

- EI15 – EI30 – EI45 – EI60 – EI70 – EI90 – EI120

- E15 – E30 – E45 – E60 – E90 – E120

- Thickness from 11mm to 48mm